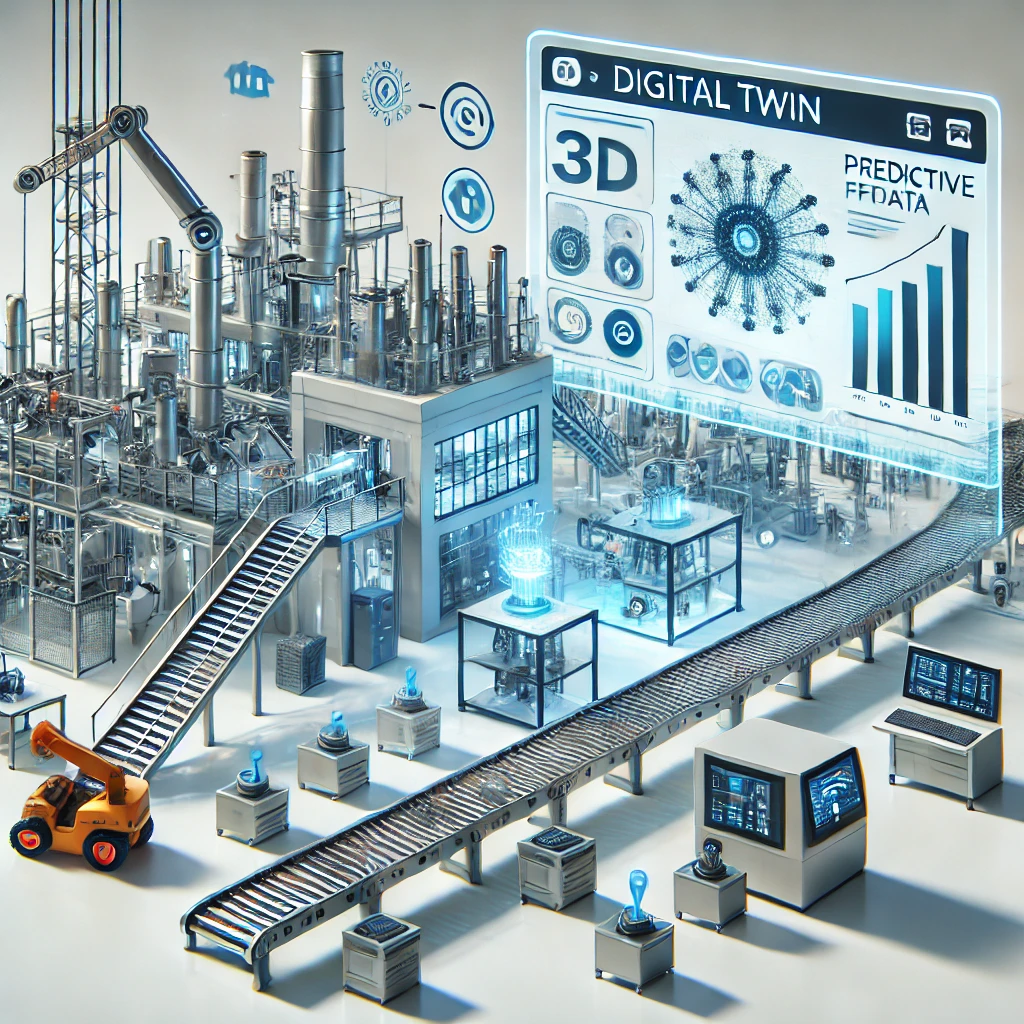

Case Study: Building a Digital Twin for a Manufacturing System

In this case study, we explore how a structured project management approach was used to develop a digital twin for a manufacturing system to optimize production efficiency.

Project Overview

-

Objective: Develop a digital twin for a smart factory to monitor and optimize production processes in real-time.

-

Stakeholders: Manufacturing company, digital twin developers, IoT specialists, production managers.

-

Budget: $500,000

-

Timeline: 12 months

-

Outcome: A fully functional digital twin integrated into the production line, capable of real-time monitoring and predictive analytics.

The project’s goal was to build a system that provides real-time insights into the production line, enabling optimization and predictive maintenance.

Phase 1: Initiating

-

Tasks:

-

Initial meeting with stakeholders to define project scope and deliverables.

-

Identify data sources from production line (e.g., sensors, IoT devices).

-

Define key metrics for optimization (e.g., production speed, equipment efficiency).

-

-

Challenges:

-

Aligning the goals of production managers and digital twin developers.

-

Ensuring the availability of IoT data from the factory.

-

Initiation involved setting clear objectives and aligning goals with stakeholder expectations. Data availability was identified as a key challenge.

Phase 2: Planning

-

Tasks:

-

Define tasks for developing the simulation model, integrating IoT data, and creating the user interface.

-

Allocate resources, including data scientists, IoT specialists, and simulation experts.

-

Create a detailed timeline for simulation model development, testing, and integration.

-

-

Challenges:

-

Estimating time required for real-time data integration.

-

Aligning team members with different technical backgrounds.

-

Planning focused on the technical challenges of building the digital twin and ensuring that the team had the necessary expertise to meet the project’s goals.

Phase 3: Executing

-

Tasks:

-

Develop the computational model simulating the production line.

-

Integrate real-time data from IoT devices with the model.

-

Test the system with live production data.

-

-

Challenges:

-

Ensuring model accuracy in predicting production outcomes.

-

Handling large volumes of real-time data without latency.

-

Execution involved building and testing the digital twin, ensuring it could handle live production data and provide accurate predictions.

Phase 4: Controlling

-

Tasks:

-

Monitor the accuracy of the predictions generated by the digital twin.

-

Adjust the model based on feedback from production managers.

-

Manage scope changes as additional functionality (e.g., predictive maintenance) was requested.

-

-

Challenges:

-

Balancing the need for additional features with the original project scope.

-

Maintaining accurate real-time predictions as production line conditions changed.

-

The control phase was essential for refining the digital twin and ensuring its accuracy in a dynamic manufacturing environment.

Phase 5: Closing

-

Tasks:

-

Deploy the digital twin into the production environment.

-

Train the production staff on using the digital twin interface.

-

Document lessons learned and key challenges for future iterations.

-

-

Challenges:

-

Ensuring seamless handover of the system to production teams.

-

Documenting insights from the project for scaling up to other manufacturing lines.

-

The closing phase involved deploying the digital twin and ensuring that the production staff could effectively use the system to optimize operations.

.pdf

.pdf